Centrifugal Fans

Series MAV. Designed for airstreams requiring very high efficiency and quiet operation.

The aerofoil cross section allows air to flow through the wheels with less turbulence than is created with a conventional backwardly inclined fan. This has two advantages: the fan is quieter; and it can be designed to function smoothly without surging or pulsation through almost its complete performance range. It gives stable operation through a wide performance range with the highly desirable non-overloading characteristics.

Centrifugal fans can be made single width single inlet (SWSI) or double width double inlet (DWDI).

Series MC.

High efficient impeller: It can be used for handling air and gases with small amount of dust or erosive materials. It can be used in high temperature. These impeller can be fitted with wear liners or hard surfaced.

Centrifugal fans can be made single width single inlet (SWSI) or double width double inlet (DWDI).

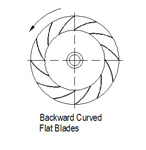

Series MV.

Backward inclined centrifugal fan designs generally represent high efficiency and cost effective centrifugal fans for both clean air and light dust loads. The absorbed power curve has a flat peak non-overloading characteristic. These fans can surge or pulsate when their air volumes are reduced to the point where they operate to the left of their pressure peaks.

Series MVR.

The radial-tipped impeller has curved blades which lie finally in a radial direction at the periphery. It has a shrouded impeller and, for a given size and speed, develops higher pressures than backward-bladed fans. It has a rising power characteristic. Medium efficiency fan suitable for most industrial applications with light to medium dust. Self cleaning blades prevent the build up of dust which would cause out of balance.

Series M for Material Handling.

The M series radial bladed impeller is non-clogging and is suitable for heavy dust loadings and materials handling. Although this design is less efficient than a backward bladed impeller, this fan can withstand the impact of large solids and the self-cleaning blade configuration prevents the accumulation of residue on the impeller. Types of radial bladed impellers and their uses include below impellers.

Type M Impeller

The radial blades are welded to the backplate with an open front. This impeller is designed for handling long stringy material, fibrous material such as textile scrap, wool, wood shavings and paper trim segments. It is not suitable for continuous paper trim handling.

Type L Impeller

The radial blades are welded to the backplate with an open front. This impeller is designed for handling long stringy material, fibrous material such as textile scrap, wool, wood shavings and paper trim segments. It is not suitable for continuous paper trim handling.

Type O Impeller (paddle)

The radial blades are welded to a heavy duty steel hub. This impeller is designed for heavy or abrasive dust, conveying of air or gases containing sticky material that would have a tendency to build up on other types of impellers. The paddle design facilitates coating or attaching replaceable bolt-on wear plates.

The radial blades are welded to a conical backplate with an open front. This impeller has polished surfaces and is designed for handling continuous paper trim. The blades of the impeller have sharp and hardened cutting edges, which can be supplied as a bolt-on option.

Series HP and Series P High Pressure Blowers

The HP series centrifugal blowers have a narrow width, fully shrouded radial bladed impeller, suitable for clean air applications such as combustion air, fluid bed aeration, blow off, cooling, conveying, drying and high pressure industrial process systems.

Multivane.

Forward curved type are characterised by a large number of curved shallow blades sloping forward or in the direction of rotation. It will handle relatively large volumes of air at a low pressure duty at lower operating speeds, but the total efficiency is somewhat less than that of backward inclined fans.

The forward curved multivane impeller is used in general ventilation for clean air applications only. It is particularly useful when a low noise level is required.

The Aerotech range of centrifugal fans can all be acoustically lagged to reduce radiated noise from the fan casing. The whole casing is double skinned and insulated with sound absorbent material. It is more economical to purchase a lagged fan than to acoustically insulate the fan casing on site to meet the necessary noise requirements.

The Aerotech plug units are solidly welded, non-overloading fans which can be square panel mounted to the side or top of oven dryer panel. The mounting panel is insulated. These fans are designed for internal operation in furnaces, ovens or kilns where air has to be exhausted, re-circulated, or distributed. Plug units eliminate ductwork and special mounting platforms.

Aerotech make a wide range of both axial and centrifugal high temperature fans. Materials are selected to have sufficient high-temperature tensile strength, creep resistance and withstand cycle fatigue. Common heat-resistant nickel-base alloys include stainless steel, Incalloy, Inconel, Multimet, Haynes etc. The fan design will take into consideration: *materials of construction for the impeller, shaft, hub and casing, *casing insulation, *bearings and lubrication. Large diameter shaft design functions as a significant heat sink and cooling can be achieved using water, oil, nitrogen or compressed air. Bearings are kept out of the airstream, the inboard bearing is moved away from the fan casing to fit a heat slinger. Bearings are selected to allow for the thermal growth ie. shaft to move lengthwise.

The Aerotech inline centrifugal fans are heavy duty industrial type, non-overloading fans which are quiet and compact. The consolidation of the centrifugal wheel in a tube with guide vanes produce a highly efficient performance characteristics comparable to scroll type centrifugal fans but with minimum space requirements similar to that of axial flow fans. The tubular design eliminates the need for duct turns and transition pieces, thus providing simpler and less costly installation. The inlet and outlet diameters are identical and the fan can be mounted vertically or horizontally.